On our way to a 100% circular Swapfiets!

On our way to a 100% circular Swapfiets!

On our way to a 100% circular Swapfiets!

On our way to a 100% circular Swapfiets!

Swapfiets has an ambitious new goal: to achieve a 100% circular product line.

Swapfiets has an ambitious new goal: to achieve a 100% circular product line.

Verfasst von

Verfasst von

Sustainability team

Sustainability team

Veröffentlicht

Veröffentlicht

Veröffentlicht

24. November 2021

24. November 2021

We haven’t reached this goal yet, but we know what needs to be done to make it happen. With this one-pager, we invite you to join us on our journey to achieve this remarkable goal. You’ll learn more about our ambition, the process and steps we’re taking to get there.

Ready? Let’s go!

Swapfiets is searching for manufacturers of circular bicycle parts

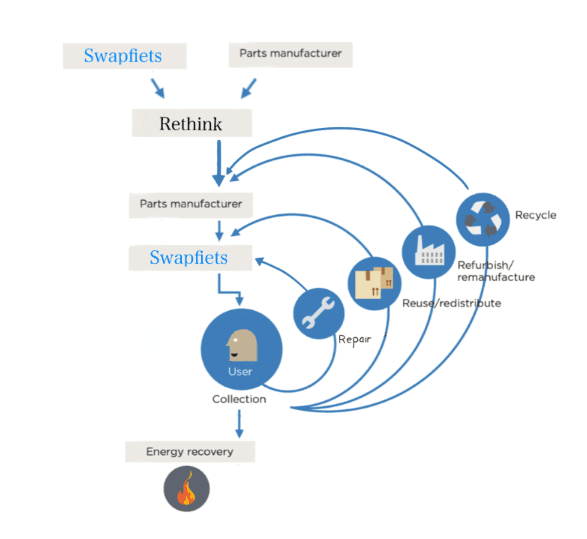

The parts will be assessed with the use of the R-strategies. R-strategies are the 7 different ways to achieve circularity with a product. When we take a look at parts alongside the R-strategies, we want to include the inflow and outflow of the used materials, as well as the life cycle of the bicycle parts.

What materials are used?

What happens with the material at the end of life?

What is the entire life cycle of the product?

Swapfiets currently focuses on three main aspects of the circular economy:

Designing products and using parts that last, based on user data;

Reusing, repairing and remanufacturing as much as possible, and;

Recycling parts at the end of their technical life (in mono-material waste streams), with the aim to realise net-zero general waste.

Due to our unique business model (product as a service), we are in search of parts with the lowest TCO (total cost of ownership) possible. For this reason, parts with a longer life expectancy are worth more. For instance, a five euro part with a life expectancy of one year is more costly (and therefore more undesirable) than a ten euro part with a life expectancy of three years.

We haven’t reached this goal yet, but we know what needs to be done to make it happen. With this one-pager, we invite you to join us on our journey to achieve this remarkable goal. You’ll learn more about our ambition, the process and steps we’re taking to get there.

Ready? Let’s go!

Swapfiets is searching for manufacturers of circular bicycle parts

The parts will be assessed with the use of the R-strategies. R-strategies are the 7 different ways to achieve circularity with a product. When we take a look at parts alongside the R-strategies, we want to include the inflow and outflow of the used materials, as well as the life cycle of the bicycle parts.

What materials are used?

What happens with the material at the end of life?

What is the entire life cycle of the product?

Swapfiets currently focuses on three main aspects of the circular economy:

Designing products and using parts that last, based on user data;

Reusing, repairing and remanufacturing as much as possible, and;

Recycling parts at the end of their technical life (in mono-material waste streams), with the aim to realise net-zero general waste.

Due to our unique business model (product as a service), we are in search of parts with the lowest TCO (total cost of ownership) possible. For this reason, parts with a longer life expectancy are worth more. For instance, a five euro part with a life expectancy of one year is more costly (and therefore more undesirable) than a ten euro part with a life expectancy of three years.

We haven’t reached this goal yet, but we know what needs to be done to make it happen. With this one-pager, we invite you to join us on our journey to achieve this remarkable goal. You’ll learn more about our ambition, the process and steps we’re taking to get there.

Ready? Let’s go!

Swapfiets is searching for manufacturers of circular bicycle parts

The parts will be assessed with the use of the R-strategies. R-strategies are the 7 different ways to achieve circularity with a product. When we take a look at parts alongside the R-strategies, we want to include the inflow and outflow of the used materials, as well as the life cycle of the bicycle parts.

What materials are used?

What happens with the material at the end of life?

What is the entire life cycle of the product?

Swapfiets currently focuses on three main aspects of the circular economy:

Designing products and using parts that last, based on user data;

Reusing, repairing and remanufacturing as much as possible, and;

Recycling parts at the end of their technical life (in mono-material waste streams), with the aim to realise net-zero general waste.

Due to our unique business model (product as a service), we are in search of parts with the lowest TCO (total cost of ownership) possible. For this reason, parts with a longer life expectancy are worth more. For instance, a five euro part with a life expectancy of one year is more costly (and therefore more undesirable) than a ten euro part with a life expectancy of three years.

"(Purchase cost (production) + life cycle cost (maintenance/service cost/storage) + disposal cost (service/storage)) / life expectancy (user count)"

"(Purchase cost (production) + life cycle cost (maintenance/service cost/storage) + disposal cost (service/storage)) / life expectancy (user count)"

As well as parts being circular, we want to show to members (and the rest of the world!) that we’re a responsible brand - by giving our bike a ‘green’ look, as well as communicating our sustainability initiatives and ethos.

In short, we need solutions in bicycle parts to reach our ambitious goal of a 100% circular. These are the principles we need to keep in mind:

Designed to last & easy to repair

Made from renewable or sustainable resources

Zero pollution anywhere in the entire life cycle

Zero waste anywhere in the entire life cycle

A sustainable ‘green’ look or story

In the following section, you can learn more about a recent project we’ve undertaken for a circular Swapfiets saddle concept study.

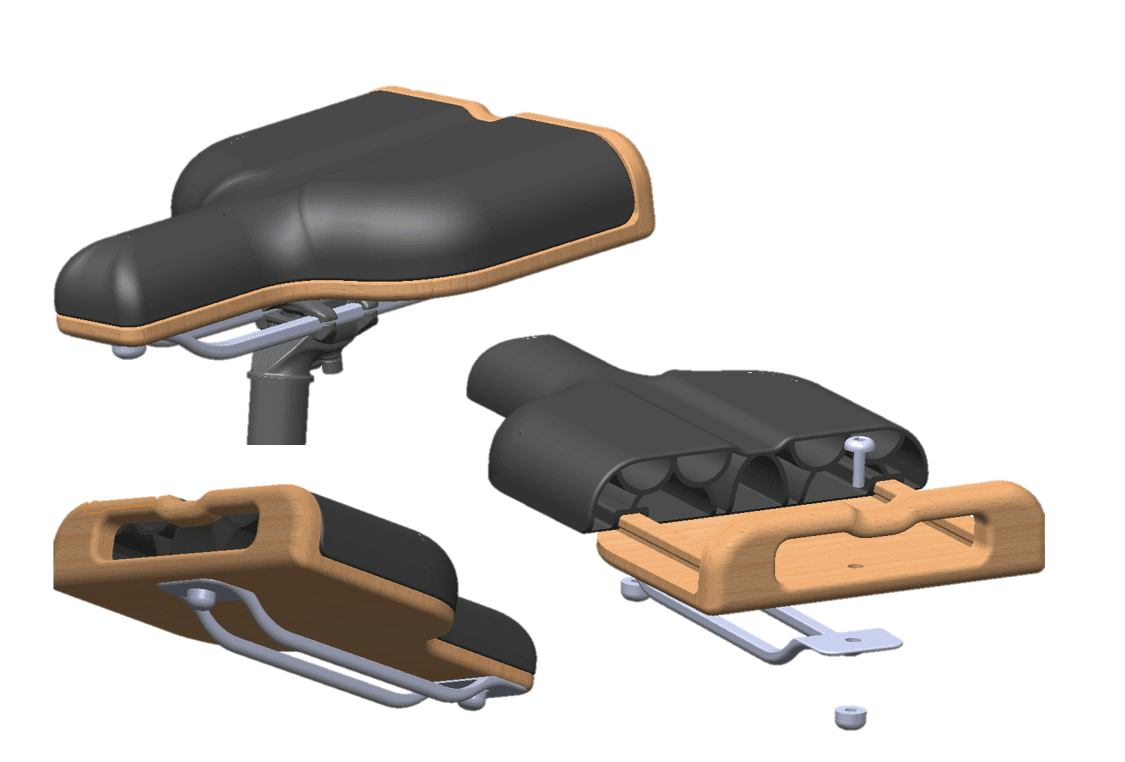

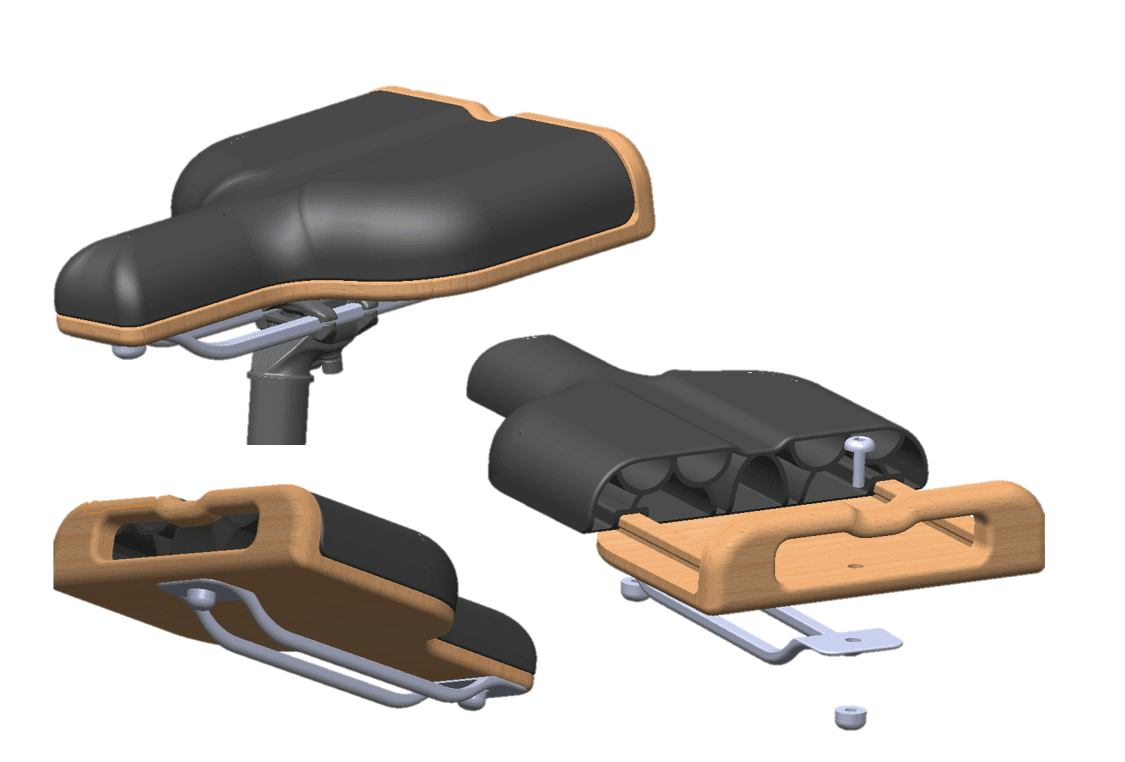

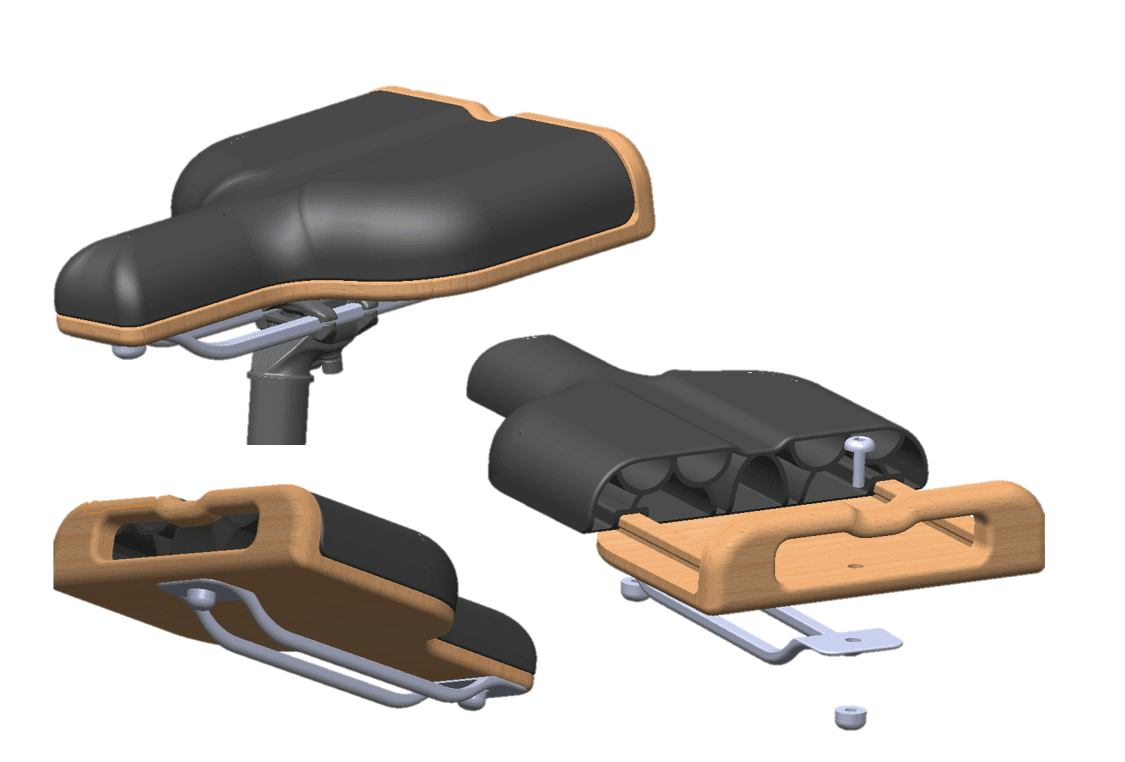

Case study: Designing a circular saddle

As a company, we often take part in life cycle analysis (LCA) of Swapfiets products. When conducting LCAs, we take a look at the sustainability of certain parts and how much total environmental impact they produce in their life cycle.

In one instance, we found that our saddle parts score poorly in these LCAs. So, in true Swapfiets fashion, we launched a project to identify just what it takes to improve the circularity potential for this element.

Throughout the project we used the R-strategy as a base to achieve circularity on different levels in the total life-cycle. Of course, we also needed to ensure that the saddle design fit our product as a service business strategy.

For us, this means a saddle that is easy to maintain for the mechanics, and is comfortable from a cost and physical point of view, for a Swapfiets member.

There are several things preventing us from achieving circularity with the current saddles on our bikes;

Mixed materials that are hard to seperate. Due to this, a clean outflow of materials and an efficient recycle process is not possible.

Non renewable/recycled materials. Some parts of these saddles aren’t made with materials that can be made from or disposed of in a circular way.

Disassembly is very hard, or sometimes not possible at all. This results in low ambition to do so, resulting in wasted parts. As these parts are relatively cheap to purchase, throwing them away is a quicker (and therefore cheaper) option than repairing.

With this in mind, we started designing our own concept:

The circular Swapfiets saddle

Why our saddle concept fits in a circular economy:

The saddle is built on a slightly more expensive frame, but is made to last longer. This, combined with an affordable production method and easily replaceable padding makes it more cost efficient in the long run.

The frame is made from bamboo, which is highly renewable. This natural material also looks sustainable - improving perception and streetcred regarding sustainable production methods.

All parts of the saddle are made from different materials that can be separated from each other quicker. Due to this, we can ensure clean outflow of different materials, thus enhancing the recycling process.

The saddle’s padding is made from a highly recyclable, flexible, mono material TPU (thermoplastic polyurethane). Because this part is easily replaceable, we can make sure the used TPU ends up in a clean material outflow.

As well as parts being circular, we want to show to members (and the rest of the world!) that we’re a responsible brand - by giving our bike a ‘green’ look, as well as communicating our sustainability initiatives and ethos.

In short, we need solutions in bicycle parts to reach our ambitious goal of a 100% circular. These are the principles we need to keep in mind:

Designed to last & easy to repair

Made from renewable or sustainable resources

Zero pollution anywhere in the entire life cycle

Zero waste anywhere in the entire life cycle

A sustainable ‘green’ look or story

In the following section, you can learn more about a recent project we’ve undertaken for a circular Swapfiets saddle concept study.

Case study: Designing a circular saddle

As a company, we often take part in life cycle analysis (LCA) of Swapfiets products. When conducting LCAs, we take a look at the sustainability of certain parts and how much total environmental impact they produce in their life cycle.

In one instance, we found that our saddle parts score poorly in these LCAs. So, in true Swapfiets fashion, we launched a project to identify just what it takes to improve the circularity potential for this element.

Throughout the project we used the R-strategy as a base to achieve circularity on different levels in the total life-cycle. Of course, we also needed to ensure that the saddle design fit our product as a service business strategy.

For us, this means a saddle that is easy to maintain for the mechanics, and is comfortable from a cost and physical point of view, for a Swapfiets member.

There are several things preventing us from achieving circularity with the current saddles on our bikes;

Mixed materials that are hard to seperate. Due to this, a clean outflow of materials and an efficient recycle process is not possible.

Non renewable/recycled materials. Some parts of these saddles aren’t made with materials that can be made from or disposed of in a circular way.

Disassembly is very hard, or sometimes not possible at all. This results in low ambition to do so, resulting in wasted parts. As these parts are relatively cheap to purchase, throwing them away is a quicker (and therefore cheaper) option than repairing.

With this in mind, we started designing our own concept:

The circular Swapfiets saddle

Why our saddle concept fits in a circular economy:

The saddle is built on a slightly more expensive frame, but is made to last longer. This, combined with an affordable production method and easily replaceable padding makes it more cost efficient in the long run.

The frame is made from bamboo, which is highly renewable. This natural material also looks sustainable - improving perception and streetcred regarding sustainable production methods.

All parts of the saddle are made from different materials that can be separated from each other quicker. Due to this, we can ensure clean outflow of different materials, thus enhancing the recycling process.

The saddle’s padding is made from a highly recyclable, flexible, mono material TPU (thermoplastic polyurethane). Because this part is easily replaceable, we can make sure the used TPU ends up in a clean material outflow.

As well as parts being circular, we want to show to members (and the rest of the world!) that we’re a responsible brand - by giving our bike a ‘green’ look, as well as communicating our sustainability initiatives and ethos.

In short, we need solutions in bicycle parts to reach our ambitious goal of a 100% circular. These are the principles we need to keep in mind:

Designed to last & easy to repair

Made from renewable or sustainable resources

Zero pollution anywhere in the entire life cycle

Zero waste anywhere in the entire life cycle

A sustainable ‘green’ look or story

In the following section, you can learn more about a recent project we’ve undertaken for a circular Swapfiets saddle concept study.

Case study: Designing a circular saddle

As a company, we often take part in life cycle analysis (LCA) of Swapfiets products. When conducting LCAs, we take a look at the sustainability of certain parts and how much total environmental impact they produce in their life cycle.

In one instance, we found that our saddle parts score poorly in these LCAs. So, in true Swapfiets fashion, we launched a project to identify just what it takes to improve the circularity potential for this element.

Throughout the project we used the R-strategy as a base to achieve circularity on different levels in the total life-cycle. Of course, we also needed to ensure that the saddle design fit our product as a service business strategy.

For us, this means a saddle that is easy to maintain for the mechanics, and is comfortable from a cost and physical point of view, for a Swapfiets member.

There are several things preventing us from achieving circularity with the current saddles on our bikes;

Mixed materials that are hard to seperate. Due to this, a clean outflow of materials and an efficient recycle process is not possible.

Non renewable/recycled materials. Some parts of these saddles aren’t made with materials that can be made from or disposed of in a circular way.

Disassembly is very hard, or sometimes not possible at all. This results in low ambition to do so, resulting in wasted parts. As these parts are relatively cheap to purchase, throwing them away is a quicker (and therefore cheaper) option than repairing.

With this in mind, we started designing our own concept:

The circular Swapfiets saddle

Why our saddle concept fits in a circular economy:

The saddle is built on a slightly more expensive frame, but is made to last longer. This, combined with an affordable production method and easily replaceable padding makes it more cost efficient in the long run.

The frame is made from bamboo, which is highly renewable. This natural material also looks sustainable - improving perception and streetcred regarding sustainable production methods.

All parts of the saddle are made from different materials that can be separated from each other quicker. Due to this, we can ensure clean outflow of different materials, thus enhancing the recycling process.

The saddle’s padding is made from a highly recyclable, flexible, mono material TPU (thermoplastic polyurethane). Because this part is easily replaceable, we can make sure the used TPU ends up in a clean material outflow.

Über Swapfiets

Über Swapfiets

Über Swapfiets

Swapfiets ist das weltweit erste "Bicycle-as-a-Service"-Unternehmen mit einem zirkulären Geschäftsmodell. Das 2014 in den Niederlanden gegründete Scale-up hat sich schnell zu einem der führenden Anbieter von Mikromobilität in Europa entwickelt und hat mittlerweile über mehr als 270.000 Mitglieder in den Niederlanden, Deutschland, Belgien, Dänemark, Frankreich, Italien und dem Vereinigten Königreich. Seit dem Frühjahr 2021 ist Swapfiets auch in Spanien (Barcelona), Österreich (Wien) und Lyon, Straßburg und Toulouse (Frankreich) tätig. Swapfiets will die Lebensqualität in europäischen Städten erhöhen, zudem strebt das Unternehmen eine zu 100% zirkuläre Produktlinie an sowie bis 2025 einen klimaneutralen Geschäftsbetrieb. Im Oktober 2022 ist Swapfiets offiziell der B Corp Gemeinschaft beigetreten, um seiner Mission mehr Nachdruck zu verleihen.

In Deutschland startete Swapfiets in 2018 und mobilisiert mittlerweile zehntausende Mitglieder in Berlin, Bonn, Braunschweig, Bremen, Düsseldorf, Frankfurt am Main, Göttingen, Halle (Saale), Hamburg, Hannover, Heidelberg, Karlsruhe, Kiel, Köln, Leipzig, Mannheim, München, Münster, Oldenburg, Potsdam, Stuttgart und Wolfsburg.

Das Konzept von Swapfiets ist einfach: gegen eine feste monatliche Gebühr steht Swapfiets-Mitgliedern immer ein funktionierendes Fahrrad zur Verfügung. Sollten unerwartet Probleme auftreten, wird das Fahrrad innerhalb von 48 Stunden repariert oder sofort und ohne zusätzliche Kosten ausgetauscht.

Swapfiets ist das weltweit erste "Bicycle-as-a-Service"-Unternehmen mit einem zirkulären Geschäftsmodell. Das 2014 in den Niederlanden gegründete Scale-up hat sich schnell zu einem der führenden Anbieter von Mikromobilität in Europa entwickelt und hat mittlerweile über mehr als 270.000 Mitglieder in den Niederlanden, Deutschland, Belgien, Dänemark, Frankreich, Italien und dem Vereinigten Königreich. Seit dem Frühjahr 2021 ist Swapfiets auch in Spanien (Barcelona), Österreich (Wien) und Lyon, Straßburg und Toulouse (Frankreich) tätig. Swapfiets will die Lebensqualität in europäischen Städten erhöhen, zudem strebt das Unternehmen eine zu 100% zirkuläre Produktlinie an sowie bis 2025 einen klimaneutralen Geschäftsbetrieb. Im Oktober 2022 ist Swapfiets offiziell der B Corp Gemeinschaft beigetreten, um seiner Mission mehr Nachdruck zu verleihen.

In Deutschland startete Swapfiets in 2018 und mobilisiert mittlerweile zehntausende Mitglieder in Berlin, Bonn, Braunschweig, Bremen, Düsseldorf, Frankfurt am Main, Göttingen, Halle (Saale), Hamburg, Hannover, Heidelberg, Karlsruhe, Kiel, Köln, Leipzig, Mannheim, München, Münster, Oldenburg, Potsdam, Stuttgart und Wolfsburg.

Das Konzept von Swapfiets ist einfach: gegen eine feste monatliche Gebühr steht Swapfiets-Mitgliedern immer ein funktionierendes Fahrrad zur Verfügung. Sollten unerwartet Probleme auftreten, wird das Fahrrad innerhalb von 48 Stunden repariert oder sofort und ohne zusätzliche Kosten ausgetauscht.

Swapfiets ist das weltweit erste "Bicycle-as-a-Service"-Unternehmen mit einem zirkulären Geschäftsmodell. Das 2014 in den Niederlanden gegründete Scale-up hat sich schnell zu einem der führenden Anbieter von Mikromobilität in Europa entwickelt und hat mittlerweile über mehr als 270.000 Mitglieder in den Niederlanden, Deutschland, Belgien, Dänemark, Frankreich, Italien und dem Vereinigten Königreich. Seit dem Frühjahr 2021 ist Swapfiets auch in Spanien (Barcelona), Österreich (Wien) und Lyon, Straßburg und Toulouse (Frankreich) tätig. Swapfiets will die Lebensqualität in europäischen Städten erhöhen, zudem strebt das Unternehmen eine zu 100% zirkuläre Produktlinie an sowie bis 2025 einen klimaneutralen Geschäftsbetrieb. Im Oktober 2022 ist Swapfiets offiziell der B Corp Gemeinschaft beigetreten, um seiner Mission mehr Nachdruck zu verleihen.

In Deutschland startete Swapfiets in 2018 und mobilisiert mittlerweile zehntausende Mitglieder in Berlin, Bonn, Braunschweig, Bremen, Düsseldorf, Frankfurt am Main, Göttingen, Halle (Saale), Hamburg, Hannover, Heidelberg, Karlsruhe, Kiel, Köln, Leipzig, Mannheim, München, Münster, Oldenburg, Potsdam, Stuttgart und Wolfsburg.

Das Konzept von Swapfiets ist einfach: gegen eine feste monatliche Gebühr steht Swapfiets-Mitgliedern immer ein funktionierendes Fahrrad zur Verfügung. Sollten unerwartet Probleme auftreten, wird das Fahrrad innerhalb von 48 Stunden repariert oder sofort und ohne zusätzliche Kosten ausgetauscht.

Am beliebtesten

Entdecke unsere neuesten Artikel

Entdecke unsere neuesten Artikel

Neuigkeiten, Tipps & mehr – direkt in dein Postfach

Neuigkeiten, Tipps & mehr – direkt in dein Postfach

Neuigkeiten, Tipps & mehr – direkt in dein Postfach